Mustard oil extraction is a crucial process in obtaining oil from mustard seeds, which is widely used in cooking and traditional medicine, particularly in South Asian cuisine. This guide outlines the different extraction methods, necessary machinery, and important considerations for establishing a mustard oil extraction plant.

Cold pressing involves cleaning mustard seeds and pressing them at low temperatures to extract the oil. This method retains the natural flavors and nutrients but yields less oil.

In hot pressing, seeds are cleaned, cooked, and pressed at elevated temperatures. This method provides a higher yield but may alter the oil's flavor and nutrient profile.

Solvent extraction utilizes a solvent (usually hexane) to achieve very high oil yields. However, this method requires complex equipment to ensure solvent residues are removed and may affect the oil's characteristics.

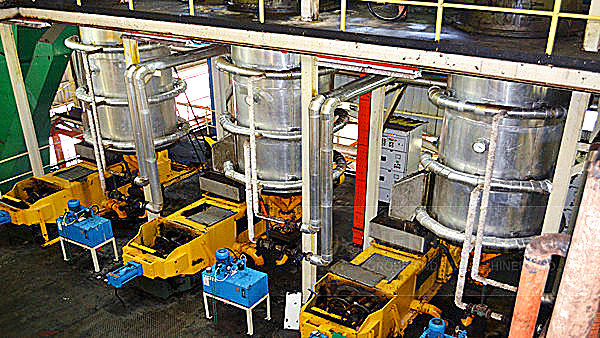

Key machinery includes:

Key considerations include:

Mustard oil extraction is a profitable business when equipped with the right machinery and setup. By selecting appropriate methods and implementing thorough quality control, entrepreneurs can successfully meet market demand while ensuring the delivery of high-quality mustard oil.