Mustard Oil Extraction: Efficient Methods and Machinery for Your Production Needs

23 12,2024

Qi'e Grain and Oil Machinery Co., Ltd.

Interactive Q&A

Explore the various methods of mustard oil extraction, including cold pressing, hot pressing, and solvent extraction. Learn about the machinery involved and key considerations for setting up a successful mustard oil extraction plant.

Introduction

Mustard oil extraction involves obtaining oil from mustard seeds, widely used in cooking and known for its medicinal properties. This article discusses the methods, machinery, and factors to consider when setting up a mustard oil extraction plant.

Methods of Mustard Oil Extraction

There are three primary methods to extract mustard oil:

- Cold Pressing: This method retains natural flavors and nutrients but yields less oil.

- Hot Pressing: Involves heating mustard seeds, resulting in quicker extraction and higher yield, though it may affect oil quality.

- Solvent Extraction: Utilizes solvents for a higher yield but requires complex equipment and can impact the oil's characteristics.

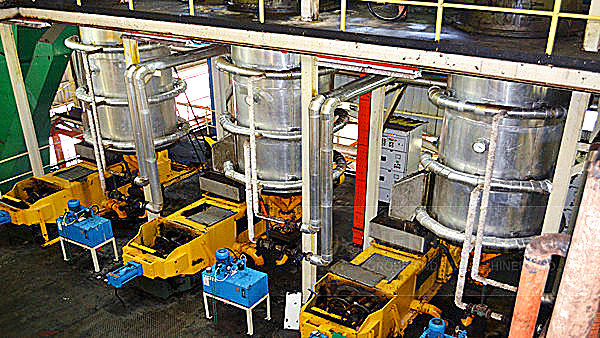

Machinery for Mustard Oil Extraction

Key machinery includes:

- Seed Cleaner: Removes impurities.

- Cooking/Kettle: Heats seeds for hot pressing.

- Oil Expeller/Press: Mechanically extracts oil.

- Filter Press: Filters out solid particles from oil.

- Storage Tanks: Stores the extracted oil.

- Packaging Unit: Packages the oil for sale.

Considerations for Setting Up a Mustard Oil Extraction Plant

For a successful setup, consider capacity, location, raw material availability, market demand, licensing, budget, quality control, and environmental compliance.

Conclusion

Mustard oil extraction can be a profitable venture with proper equipment and setup. Choose the appropriate extraction method and ensure quality control for success in your mustard oil production business.